The Efficient ASRS Shuttle System by HWArobotics

Switzerland is known for its innovative technology, and one such groundbreaking invention is the ASRS shuttle system developed by HWArobotics. This article explores the features and benefits of this advanced automated storage and retrieval system.

An Efficient Buffering Solution: SLS300

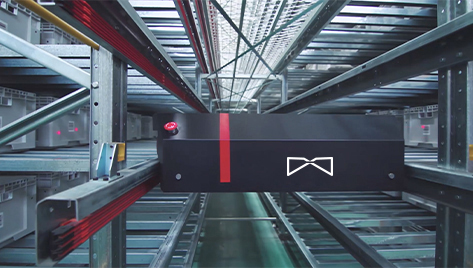

The SLS300 shuttle robot system offered by HWArobotics provides an efficient buffering solution for totes and cartons. With a fixed width load handling device designed to handle standard size products, it ensures smooth operations in various industries. This state-of-the-art system offers flexible specification options, better space utilization, and more reliable operating equipment.

With its ability to handle fully automated crates and cartons with ease, the SLS300 guarantees efficient throughput while maintaining optimal product integrity. Its advanced design allows for seamless integration into existing warehouse setups, making it an ideal choice for businesses looking to enhance their storage capabilities.

A Versatile Mixed Storage Solution: SLS400

HWArobotics also offers the SLS400 AS/RS shuttle system specifically designed for mixed storage requirements. This variable tote-handling solution provides excellent storage density without compromising on accessibility or efficiency.

The SLS400 enables businesses to store different types of products together in a single unit, eliminating the need for separate storage areas. By optimizing space utilization through intelligent stacking algorithms, this versatile system maximizes warehouse capacity while ensuring easy access to stored items when needed.

Enhancing Warehouse Efficiency with Automation

In today’s fast-paced business environment, automation plays a crucial role in improving operational efficiency. The ASRS shuttle systems provided by HWArobotics offer significant advantages over traditional manual processes.

By automating material handling tasks such as picking, sorting, and storage, these systems reduce human error and increase overall productivity. They also minimize the risk of workplace accidents and injuries associated with manual labor.

Furthermore, the ASRS shuttle systems enable businesses to optimize their inventory management by providing real-time data on stock levels, order fulfillment rates, and product movement patterns. This valuable information allows for better decision-making and improved customer satisfaction.

The Future of Warehousing

In conclusion, HWArobotics’ ASRS shuttle system revolutionizes warehouse operations by offering efficient buffering solutions for various products. With its advanced features like fixed width load handling devices and flexible specification options, it ensures optimal space utilization while maintaining reliable equipment performance.

As automation continues to shape industries worldwide, the ASRS shuttle system proves to be a game-changer in enhancing warehouse efficiency. By embracing this innovative technology from HWArobotics, businesses can stay ahead of the competition while delivering exceptional service to their customers.